- tyler@kirail.com

- +86 15603721115

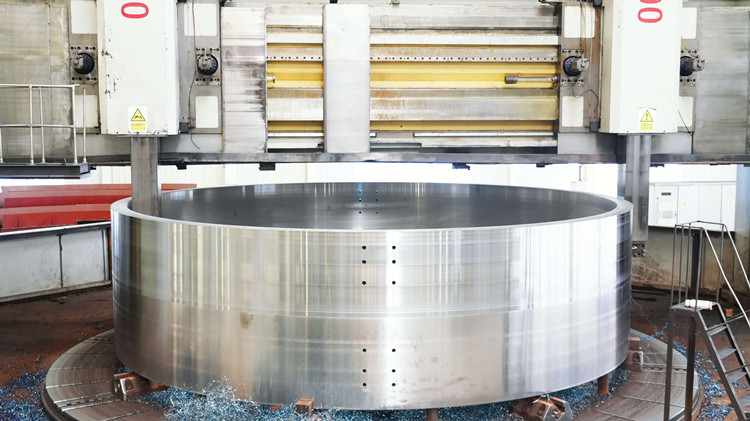

Since the dawn of humanity, metalworking technology has provided strength, toughness, reliability and top quality to a wide range of products. Today, as operating temperatures, loads and stresses continue to increase, these benefits of forged components are even more important.

Forged components are designed to withstand the highest loads and stresses. Recent advances in forging technology have greatly expanded the performance range of forgings.

From an economic point of view, forged products are attractive because of their inherent superior reliability, improved tolerance capabilities and the greater efficiency with which forgings can be machined and further processed through automated methods.

The structural reliability achieved by forgings is unmatched by any other metalworking process. There are no air pockets or voids inside the forgings that can cause unexpected failures under stress or impact. In general, the forging process helps improve the chemical segregation of the forging blank by moving the centerline material to various locations throughout the forging.

For the designer, the structural integrity of the forging means a safety factor based on the material that will react predictably to its environment without the need for expensive special treatments to correct internal defects.

For production employees, the structural reliability of forgings means reduced inspection requirements, uniform response to heat treatment, and consistent machinability, all of which help increase production speed and reduce costs.