- tyler@kirail.com

- +86 15603721115

Improving efficiency and quality in the forging industry requires a comprehensive approach, focusing on process optimization, intelligent transformation, automated production, intelligent temperature control, mold life extension, improved heating quality, application of high-efficiency lubricants, and the promotion of high-tech applications. The following are specific strategies:

1. Process Optimization: Streamlining Processes and Improving Techniques

1) Selection of Forging Methods:

Choosing the appropriate forging method based on product characteristics is crucial. Open die forging is suitable for complex shapes and small batches, while closed die forging is more suitable for large batches and regularly shaped products. Closed die forging offers significantly higher repeatability and dimensional accuracy than open die forging, making it ideal for automated production.

2) Control of Forging Temperature:

Heating temperature is a critical factor affecting forging quality. Excessively high temperatures can lead to overheating and coarse grain size in the metal, reducing material performance; excessively low temperatures make plastic deformation difficult and increase deformation force. By optimizing the heating process, such as using induction heating and continuous heating furnaces, more precise temperature control can be achieved, reducing heating time and improving production efficiency.

3) Improvement of Deformation Process:

Optimizing the deformation sequence and amount can reduce the amount of subsequent processing. In addition, intelligent heating furnaces can achieve on-demand heating, reducing energy consumption.

2. Intelligent Transformation: Digitalization and Big Data Applications

1) Digital Production Management System:

Establishing a digital production management system allows for real-time monitoring of production data, including equipment operating status, energy consumption, and output. Through data analysis, production bottlenecks can be identified and production plans optimized.

2) Intelligent Production Scheduling Algorithm:

Automatically adjusting equipment operating parameters based on order urgency increases equipment utilization from 65% to 85%, increasing daily output by 30%, meeting customer demand for rapid delivery while avoiding capacity waste.

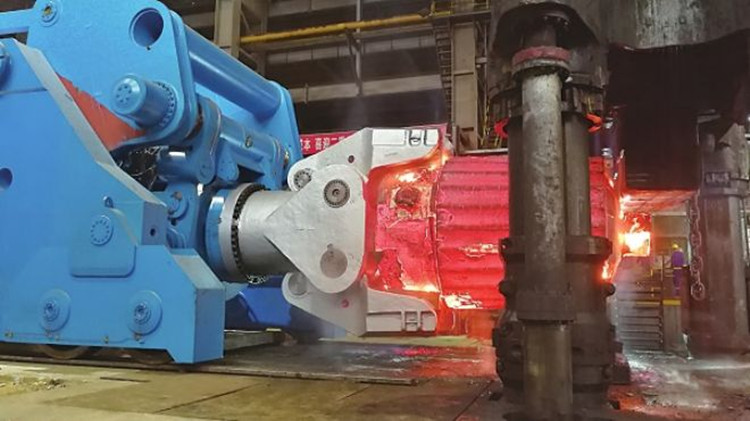

3. Automated Production: Freeing Up Manpower and Precisely Improving Efficiency

1) Fully Automated Production Line:

Introducing a fully automated production line allows robotic arms to perform high-precision forging tasks 24 hours a day. This reduces manpower input by 40% per production line while increasing capacity by more than 25%.

2) Intelligent Production Scheduling Algorithm:

Automatically adjusts equipment operating parameters based on order urgency, increasing equipment utilization from 65% to 85%, and increasing daily output by 30%, meeting customers' rapid delivery needs while avoiding capacity waste.

4. Intelligent Temperature Control System: Reduced Energy Consumption, Improved Quality

1) Electromagnetic Induction Heating Technology:

The new electromagnetic induction heating technology can reduce energy consumption by 35% and control temperature fluctuations within ±5℃ through real-time sensors.

2) Improved Product Consistency:

After a factory specializing in automotive parts forging introduced an intelligent system, the standard deviation of product hardness decreased from 3.2 to 0.8, and the customer return rate decreased by 90%, successfully entering the high-end supply chain market and increasing profit margins by 18%.

5. Improved Mold Life: Optimized Design and Maintenance

1) The mold cavity surface should be polished during mold manufacturing:

The required surface roughness should be achieved to avoid grinding softening.

2) The mold must be preheated during use:

Preheat to 150~250℃, select a reasonable initial forging temperature, and prevent low-temperature forging.

3) Remove scale promptly during forging:

Pay attention to mold cooling and lubrication.

6. Improved Heating Quality: Reduced Oxidation and Decarburization

1) Investment in non-oxidizing heating furnaces:

This will improve the oxidation and decarburization problems that occur in steel during the heating process.

2) Hydrogen embrittlement problems during titanium alloy heating:

Measures need to be taken to prevent material contamination.

7. Application of High-Efficiency Lubricants: Reducing Friction Coefficient

1) The role of lubricants:

They can not only reduce the friction coefficient but also protect forgings from contamination and extend mold life.

2) Promotion of new lubricants:

Although my country has adopted graphite, glass, and FR series lubricants, the variety is still limited, and the promotion is not yet widespread.

8. Promotion of High Technology: Computer Simulation and System Management

1) Computer simulation technology:

It can provide a reasonable mold structure and extend mold life.

2) System management technology:

It can improve the production environment, increase productivity, and reduce production costs.

Final Summary

Through the comprehensive application of the above strategies, the efficiency and quality of the forging industry can be significantly improved, promoting high-quality development of the industry.