- tyler@kirail.com

- +86 15603721115

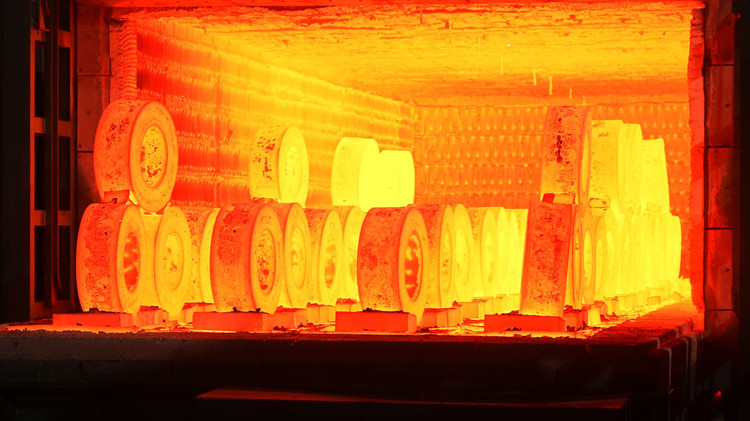

New energy-efficient mobility concepts require optimized designs by downsizing components and selecting corrosion-resistant materials with a high strength-to-density ratio. Component downsizing can be achieved by structural optimization or by replacing heavy materials with lighter high-strength materials. In this context, forging plays an important role in the manufacture of load-optimized structural components.

The Institute of Metal Forming and Metal Forming Machinery (IFUM) develops various innovative forging technologies. In terms of structural optimization, different strategies for local strengthening of components are investigated. Local induced strain hardening can be achieved by cold forging under superimposed hydrostatic pressure.

In addition, controlled martensitic zones can be created by forming induced phase transformations in metastable austenitic steels. Other research focuses on replacing heavy steel components with high-strength nonferrous alloys or mixed material compounds.

Several forging processes for magnesium, aluminum, and titanium alloys for different aerospace and automotive applications have been developed. The entire process chain from material characterization to simulation-based process design to part production has been considered. The feasibility of forging complex geometries with these alloys has been demonstrated.

Despite the difficulties caused by machine noise and high temperatures, acoustic emission (AE) technology has been successfully applied for the online monitoring of forging defects. New AE analysis algorithms have been developed to detect and classify different signal patterns caused by various events such as product/die cracking or die wear.

In addition, the feasibility of the forging technology has been demonstrated by finite element analysis (FEA). For example, the integrity of the forging die with respect to thermomechanical fatigue crack initiation and the ductile damage of the forgings have been studied with the help of cumulative damage models.