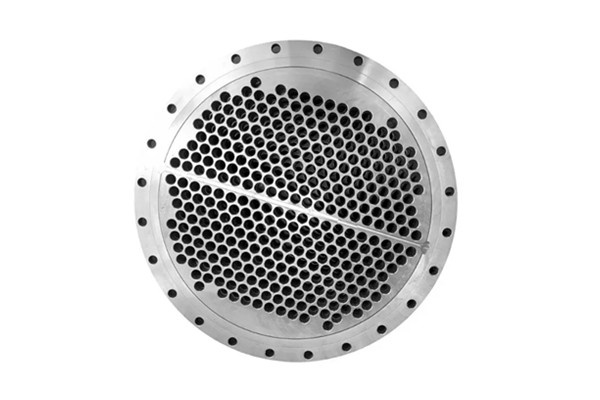

Forged tubesheets are usually made from round forgings and are drilled to allow tubes to be placed relative to each other in a precise position and shape. Tubesheets are used to support and insulate tubes in heat exchangers and boilers to ensure efficient heat transfer, or to support filter elements.

The tubes are fixed to the tubesheets by hydraulic or roll expansion. Tubesheets may be covered with cladding materials to act as corrosion barriers and insulators.

In a shell and tube heat exchanger, two tubesheets support the ends of the tubes. The tubesheets are in contact with the fluid on the shell and tube sides and must be corrosion resistant and tightly sealed. Many heat exchanger design codes and standards require the use of forged tubesheets.

Forged tubesheets are generally produced by die forging, have a fine crystal structure, high strength, and are more expensive than other tubesheets.

Kingrail Parts can manufacture forged tubesheets in a variety of material grades. We are able to produce tubesheets to meet any customer requirements.