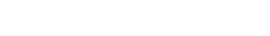

Nominal

pipe size | Thread

density | Thread

Pitch | Hand-Tight Engagement | Effective Thread | Overall

Length | Actual Outside

Diameter OD | Tap drill |

inch | mm | Length | Turns | Diameter | Length | Turns | Diameter | inch | mm | inch | mm |

inch | inch⁻¹ | inch | mm | inch | - | inch | inch | - | inch | inch | inch | mm | inch | mm |

1/16 | 27 | 0.03703704 | 0.9407 | 0.1600 | 4.32 | 0.28118 | 0.2611 | 7.05 | 0.2875 | 0.3896 | 0.313 | 7.95 | - | - |

1/8 | 27 | 0.03703704 | 0.9407 | 0.1615 | 4.36 | 0.37360 | 0.2639 | 7.13 | 0.38000 | 0.3924 | 0.405 | 10.287 | 0.339 | 8.6106 |

1/4 | 18 | 0.05555555 | 1.41111 | 0.2278 | 4.10 | 0.49163 | 0.4018 | 7.23 | 0.50250 | 0.5946 | 0.540 | 13.716 | 7/16 | 11.113 |

3/8 | 18 | 0.05555555 | 1.41111 | 0.2400 | 4.32 | 0.62701 | 0.4078 | 7.34 | 0.63750 | 0.6006 | 0.675 | 17.145 | 37/64 | 14.684 |

1/2 | 14 | 0.07142857 | 1.8143 | 0.3200 | 4.48 | 0.77843 | 0.5337 | 7.47 | 0.79178 | 0.7815 | 0.840 | 21.3360 | 23/32 | 18.2563 |

3/4 | 14 | 0.07142857 | 1.8143 | 0.3390 | 4.75 | 0.98887 | 0.5457 | 7.64 | 1.00178 | 0.7935 | 1.050 | 26.6700 | 59/64 | 23.4156 |

3/4 | 11 1/2 | 0.08695652 | 2.2087 | 0.4000 | 4.60 | 1.23863 | 0.6828 | 7.85 | 1.25631 | 0.9845 | 1.315 | 33.4010 | 1 5/32 | 29.3688 |

1 1/4 | 11 1/2 | 0.08695652 | 2.2087 | 0.4200 | 4.83 | 1.58338 | 0.7068 | 8.13 | 1.60131 | 1.0085 | 1.660 | 42.1640 | 1 1/2 | 38.1000 |

1 1/2 | 11 1/2 | 0.08695652 | 2.2087 | 0.4200 | 4.83 | 1.82234 | 0.7235 | 8.32 | 1.84131 | 1.0252 | 1.900 | 48.2600 | 1 47/64 | 44.0531 |

2 | 11 1/2 | 0.08695652 | 2.2087 | 0.4360 | 5.01 | 2.29627 | 0.7565 | 8.70 | 2.31630 | 1.0582 | 2.375 | 60.3250 | 2 7/32 | 56.3563 |

2 1/2 | 8 | 0.12500000 | 3.1750 | 0.6820 | 5.46 | 2.76216 | 1.1375 | 9.10 | 2.79063 | 1.5712 | 2.875 | 73.0250 | 2 5/8 | 66.6750 |

3 | 8 | 0.12500000 | 3.1750 | 0.7660 | 6.13 | 3.38850 | 1.2000 | 9.60 | 3.41563 | 1.6337 | 3.500 | 89.9000 | 3 1/4 | 82.5500 |

3 1/2 | 8 | 0.12500000 | 3.1750 | 0.8210 | 6.57 | 3.88881 | 1.2500 | 10.00 | 3.91563 | 1.6837 | 4.000 | 101.6000 | 3 3/4 | 95.2500 |

4 | 8 | 0.12500000 | 3.1750 | 0.8440 | 6.75 | 4.38713 | 1.3000 | 10.40 | 4.41563 | 1.7337 | 4.500 | 114.3000 | 4 1/4 | 107.9500 |

5 | 8 | 0.12500000 | 3.1750 | 0.9370 | 7.50 | 5.44929 | 1.4063 | 11.25 | 5.47863 | 1.8400 | 5.563 | 141.3002 | 5 9/32 | 134.1438 |

6 | 8 | 0.12500000 | 3.1750 | 0.9580 | 7.66 | 6.50597 | 1.5125 | 12.10 | 6.54063 | 1.9462 | 6.625 | 168.2750 | 6 11/32 | 161.1313 |

6 | 8 | 0.12500000 | 3.1750 | 0.9580 | 7.66 | 6.50597 | 1.5125 | 12.10 | 6.54063 | 1.9462 | 6.625 | 168.2750 | 6 11/32 | 161.1313 |

8 | 8 | 0.12500000 | 3.1750 | 1.0630 | 8.50 | 8.50003 | 1.7125 | 13.70 | 8.54063 | 2.1462 | 8.625 | 219.0750 | - | - |

10 | 8 | 0.12500000 | 3.1750 | 1.2100 | 9.68 | 10.62094 | 1.9250 | 15.40 | 10.66563 | 2.3587 | 10.750 | 273.0500 | - | - |

12 | 8 | 0.12500000 | 3.1750 | 1.3600 | 10.88 | 12.61781 | 2.1250 | 17.00 | 12.66563 | 2.5587 | 12.750 | 323.8500 | - | - |

14 | 8 | 0.12500000 | 3.1750 | 1.5620 | 12.50 | 13.87263 | 2.2500 | 18.00 | 13.91563 | 2.6837 | 14.000 | 355.6000 | - | - |

16 | 8 | 0.12500000 | 3.1750 | 1.8120 | 14.50 | 15.87575 | 2.4500 | 19.60 | 15.91563 | 2.8837 | 16.000 | 406.4000 | - | - |

18 | 8 | 0.12500000 | 3.1750 | 2.0000 | 16.00 | 17.87500 | 2.6500 | 21.20 | 17.91563 | 3.0837 | 18.000 | 457.2000 | - | - |

20 | 8 | 0.12500000 | 3.1750 | 2.1250 | 17.00 | 19.87031 | 2.8500 | 22.80 | 19.91563 | 3.2837 | 20.000 | 508.0000 | - | - |

24 | 8 | 0.12500000 | 3.1750 | 2.3750 | 19.00 | 23.86094 | 3.2500 | 26.00 | 23.91563 | 3.6837 | 24.000 | 609.6000 | - | - |

Kingrail Parts stocks flanges in a variety of sizes and specifications.

Frequently Asked Questions (FAQ)

1. What is a threaded flange?

A threaded flange is a pipe flange that has internal threads on the hole that screw directly onto the external threads of the pipe.

This design eliminates the need for welding, making it a convenient option for pipes that cannot be welded or where welding is not appropriate.

2. What are the advantages of a threaded flange?

A threaded flange can be easily screwed onto a pipe without the need for welding or additional sealing methods, making it faster and more straightforward to install or remove.

Threaded flanges are generally less expensive than welded or slip-on flanges because they do not require welding labor or specialized equipment.

3. When should a threaded flange be used?

Threaded flanges are best used in applications where pressure is not very high, as they are not designed to withstand the pressures associated with high-pressure systems.

4. For systems that require regular maintenance or replacement of parts, such as temporary pipe installations or test fixtures, threaded flanges can be easily assembled and disassembled.

5. When should threaded flanges not be used?

Threaded flanges are not suitable for systems involving high internal pressures, as the threads may fail or leak under such pressures.

In applications with high vibration, threaded flanges may not be held firmly for long, resulting in loosening and potential leaks.

5. How to install threaded flanges?

Clean the pipe threads and the inside of the flange to ensure a secure and leak-free connection. Align the threaded flange with the pipe and screw it onto the pipe threaded end by hand until it is tight.

Use a wrench to further tighten the flange onto the pipe. Be careful not to overtighten, as this may damage the threads or pipe. You can also use thread sealant or Teflon tape to prevent leaks in low-pressure systems to ensure a tight seal.

Get more help

Kingrail Parts offers a wide range of forged flanges. If you need a forged flange, please contact us. Our flange experts will give you the best advice and a free quote.