- tyler@kirail.com

- +86 15603721115

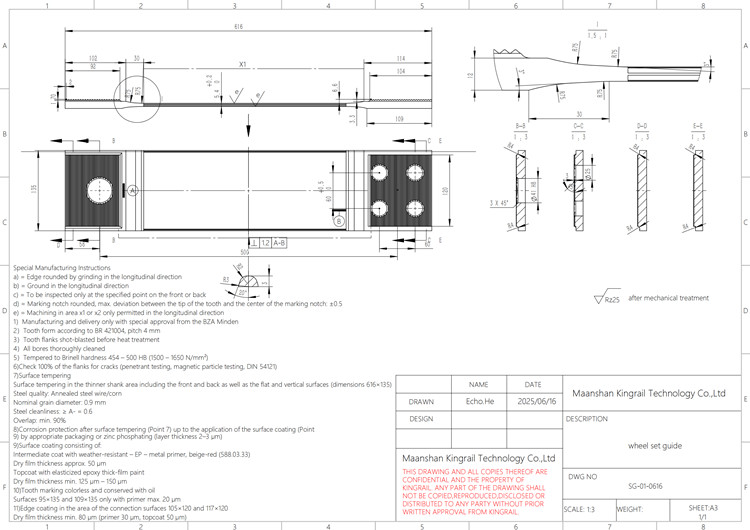

We all know that forging is just a metal forming technology that is processed according to drawings. Therefore, for China custom forging, drawing design is the first step in manufacturing metal parts. Such drawings are usually designed using computer software such as DXF, Parasolid, Step, IGS, Solidworks, Catia, Pro-Engineer, etc.

Usually, drawings include drawing number, material, unit weight, size, tolerance, notes, etc. All these factors must be accurately marked on the drawing so that the forging company can customize the right part you need. Of course, if there is no drawing, samples can also be provided.

1. Drawing number

The drawing number is used to name the forged part so that we can check the part accordingly. In most cases, the drawing number (such as FLY151006) consists of letters and numbers (the letters can be the abbreviation of the company name, and the numbers can be the date or product serial number). When communicating with customers, both of us know which one we are talking about. For the next order, the purchaser only needs to inform the drawing number in the purchase order.

2. Material

The material plays a decisive role in the performance of forgings. In the field of forging, we can choose stainless steel, carbon steel, alloy steel and aluminum. The material is mainly determined by the purpose of the product. Therefore, the designer must indicate the material specifications on the drawing, such as 20#, 45#, SS304, etc.

3. Unit weight

The unit weight is marked on the drawing to give the supplier a better understanding of whether the product is suitable for manufacturing. And what kind of metal bar will be used and how long the metal bar will be cut for forging. In this way, we can correctly perform cost analysis. In short, it will help us calculate the price in the shortest time.

4. Dimensions and tolerances

In order to describe the shape of the forging, the designer will mark the dimensions of each part (length, width, thickness, outer diameter, inner diameter, chamfer, etc.). The main dimensions will also be marked with tolerances to ensure that the forgings can be assembled smoothly. For strict tolerances, we can meet them through precision machining. Unspecified tolerances may also be marked at the bottom of the drawing.

5. Notes

Notes contain some information that is important to the forging manufacturer, which is usually also marked on the right side of the drawing. These notes can be alternative materials, mechanical property requirements, heat treatment requirements, testing requirements, etc.