- tyler@kirail.com

- +86 15603721115

Casting and forging have always been common metal processing processes. Due to the differences in the casting and forging processes themselves, there are many differences in the products produced by the two processing methods.

Castings are materials cast as a whole in a mold, with uniform stress distribution and no restrictions on the direction of pressure; while forgings are squeezed by forces in the same direction, so their internal stress is directional and can only withstand directional pressure.

About forging

What is forging?

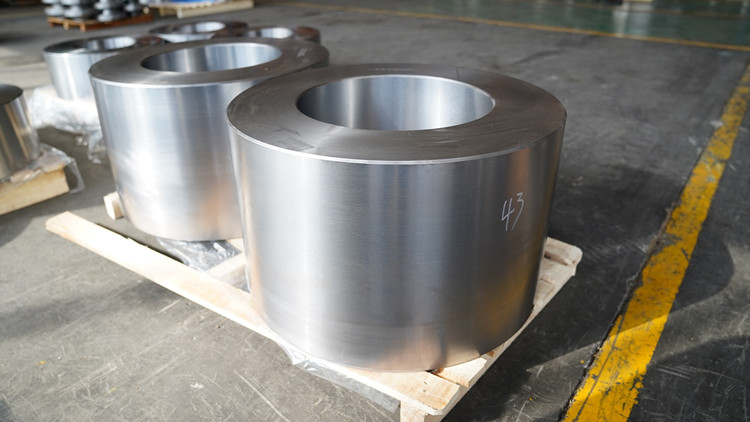

A processing method that uses forging machinery to apply pressure to metal billets to cause them to undergo plastic deformation in order to obtain forgings with certain mechanical properties, shapes and sizes.

The role of forging

Forging can eliminate casting pores and welding holes in metals, and the mechanical properties of forgings are generally better than those of castings of the same material. Important parts in machinery with large loads and harsh working conditions, except for simple-shaped plates, profiles or welded parts that can be processed by rolling methods, are mostly forged.

Forging can be divided into

1. Open forging (free forging)

Including wet sand mold, dry sand mold, chemical hardening sand mold;

2. Closed die forging

Special casting using natural mineral sand and gravel as the main molding materials (such as investment casting, mud mold casting, foundry shell casting, negative pressure casting, full mold casting, ceramic casting, etc.);

3. Other casting classification methods

According to the deformation temperature, forging can be divided into hot forging (processing temperature is higher than the recrystallization temperature of the billet metal), warm forging (lower than the recrystallization temperature), and cold forging (at room temperature).

Forging materials

Forging materials are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, titanium, copper and their alloys. The original state of the material includes bars, ingots, metal powder, liquid metal, etc.

The ratio of the cross-sectional area of the metal before deformation to the cross-sectional area of the die after deformation is called the forging ratio. The correct selection of the forging ratio is closely related to improving product quality and reducing costs.

About Casting

What is Casting

It is a process of melting metal into a liquid that meets certain requirements, pouring it into a mold, cooling, solidifying, and cleaning it to obtain a casting (part or blank) of predetermined shape, size, and performance. It is a basic process in the modern machinery manufacturing industry.

The cost of raw materials for casting production is low, and it can better reflect its economy for parts with complex shapes, especially those with complex inner cavities; at the same time, casting has a wide adaptability and good comprehensive mechanical properties.

Casting production requires a large amount of materials (such as metal, wood, fuel, modeling materials, etc.) and equipment (such as metallurgical furnaces, sand mixers, molding machines, core making machines, sand dropping machines, shot blasting machines, cast iron plates, etc.), and will produce dust, harmful gases, noise, etc., polluting the environment.

Casting is one of the earliest metal heat processing technologies mastered by humans, with a history of about 6,000 years. In 3200 BC, copper frog castings appeared in the Mesopotamian Valley.

From the 13th century BC to the 10th century BC, China entered the heyday of bronze casting, and the craftsmanship level was quite high. Representative products of ancient casting include the 875-kilogram Simuwu square tripod from the Shang Dynasty, the Yizun plate from the Warring States Period, and the light-transmitting mirror from the Western Han Dynasty.

There are many types of casting technology, which can be divided into the following categories according to the molding method:

1. Ordinary sand casting

Including wet sand mold, dry sand mold, and chemical hardening sand mold;

2. Sand and gravel special casting

Special casting using natural mineral sand and gravel as the main molding materials (such as investment casting, mud mold casting, foundry shell casting, negative pressure casting, solid mold casting, ceramic casting, etc.);

3. Metal special casting

Special casting using metal as the main casting material (such as metal mold casting, pressure casting, continuous casting, low-pressure casting, centrifugal casting, etc.).