1. Slip-on flange welding type

There are two main types of slip-on (SO) flanges: SO welded plate flanges and SO welded hub steel pipe flanges.

This flange combines the advantages of integral flanges and loose flanges, with a simple design and easy processing, so slip-on flange welding is widely used in various fluid pipelines.

2. Raised slip-on flange

The bottom surface of the raised slip-on flange has a small protrusion. During installation, this convex surface can be used as a designated placement area for the gasket, thereby enhancing the overall sealing performance.

3. RTJ slip-on flange

For RTJ slip-on flanges, a small groove is precisely machined on its convex part. This unique RTJ design is designed for high-pressure applications and provides a secure groove for the installation of the gasket, ensuring a better sealing than the RF type.

Kingrail Parts stocks flanges in a variety of sizes and specifications.

Frequently Asked Questions (FAQ)

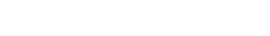

1. What is a slip-on flange?

A slip-on flange is a pipe flange that slips over the end of a pipe and is secured with bolts that align with pre-drilled holes.

Its inside diameter is designed to be slightly larger than the pipe so that it can be easily "slipped in" before being secured. It is typically used in low to medium pressure systems.

2. What are the advantages of a slip-on flange?

The design allows for quick assembly without complicated welding or alignment, making it ideal for projects with tight deadlines.

Because slip-on flanges have a simpler design and manufacturing process, they are generally less expensive than other flanges, such as weld neck flanges or blind flanges.

3. When should a slip-on flange be used?

These flanges are not designed to handle high pressure or high temperature systems, so they are ideal for standard applications where pressure is not a concern.

Slip-on flanges are a cost-effective option when budget is a key factor and the application does not require the strength and durability of more expensive flanges.

4. When should a slip-on flange not be used?

Slip-on flanges are not designed to work in high-pressure systems and may fail or leak under extreme pressure.

Slip-on flanges are not designed to provide the same vibration resistance as other types of flanges, such as welded or socket weld flanges, which can cause the connection to fail over time.

5. How do I install a slip-on flange?

Make sure the end of the pipe and inside the slip-on flange are free of debris. Slip the slip-on flange over the end of the pipe. The flange should fit snugly, but without force.

Rotate the flange as needed until the bolt holes on the flange align with the corresponding holes on the pipe or fitting. Insert the appropriate bolts through the aligned holes.

Tighten the bolts in a crisscross pattern to evenly distribute pressure and achieve a proper seal.

Get more help

Kingrail Parts offers a wide range of forged flanges. If you need a forged flange, please contact us. Our flange experts will give you the best advice and a free quote.