- tyler@kirail.com

- +86 15603721115

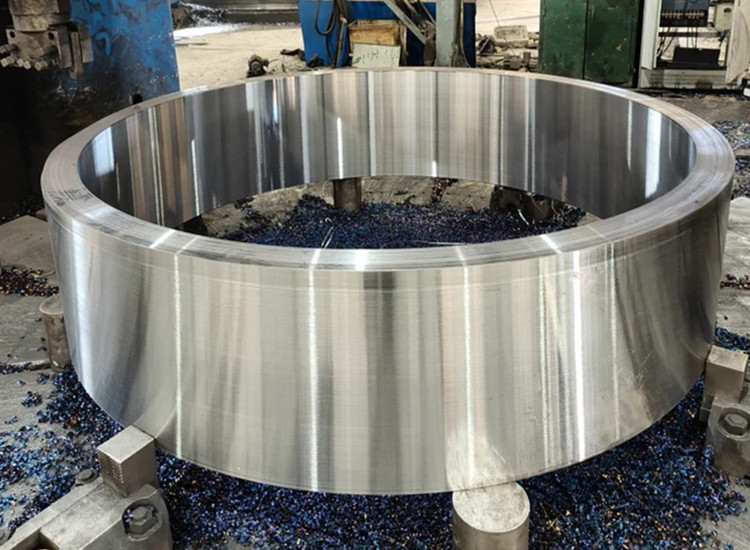

High-quality large forgings can well control the dimensional tolerance of products and reduce the amount of machining. However, when making large forgings, be careful not to choose defective large forgings. If defective large forgings are selected, it will seriously affect the use of engineering and equipment, and there will be certain risks. So, how to choose large forgings?

1. Look at the surface of the forging.

If there are cracks, folds, creases, pressure pits, orange peel, bubbles, spots, corrosion pits, bruises, foreign matter, incompleteness, pits, lack of meat, scratches and other defects on the surface of large forgings, it is recommended that you do not buy them.

2. Analysis of machining allowance size Large forgings also have relevant requirements for the material of large forgings.

The blank cannot be used as a forging for forging. The forging ratio of parts of different shapes should be guaranteed. When producing round steel forgings of similar sizes, during the forging process, such as temperature, forging frequency, pressure, etc., strict requirements should not be met. Metal crystals in forgings Large forgings are cut more finely, and the metal fibers of the raw materials will not be damaged during forging processing, and the metal texture can be made smoother.

3. Strict technical requirements.

Large forgings should meet international safety standards, and the material must be consistent with the material of the parts. The chemical composition should also meet national unified standards, and a list of materials should be issued. The main method to reduce the hydrogen content in steel is vacuum degassing or vacuum pouring of molten steel during steelmaking. For some large forgings with higher requirements, the electroslag remelting process can be used to further improve the purity of the steel. Post-forging heat treatment: dehydrogenation annealing to diffuse hydrogen from the steel.