- tyler@kirail.com

- +86 15603721115

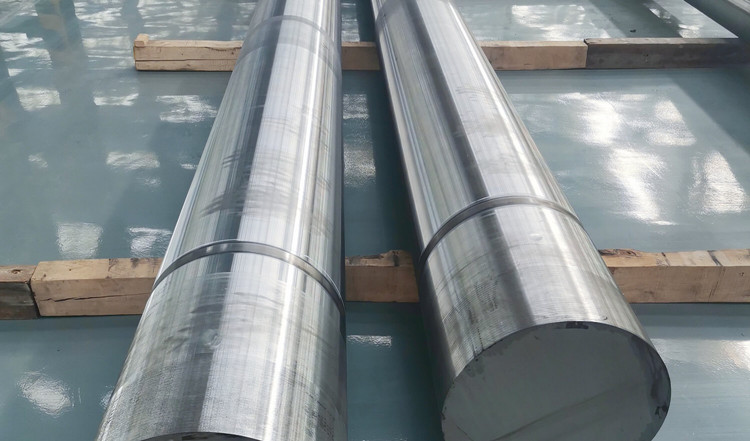

Various problems may be encountered during the forging process. Let us introduce them to you in detail below.

1. Aluminum alloy oxide film

The oxide film of aluminum alloy is usually located on the die forging belly, close to the parting surface. The fracture surface has two characteristics: one is flatness, with colors ranging from silver gray, light yellow to brown and dark brown; the other is that the spots are small, dense and shiny. The aluminum alloy oxide film is formed during the smelting and forging process when the exposed molten surface interacts with water vapor or other metal oxides in the air, and is formed in the liquid metal involved in the casting process. The oxide film in forgings and die forgings has no obvious effect on the longitudinal mechanical properties.

2. Carbide segregation

According to the analysis of Hebei Forging Plant, carbide segregation usually occurs in alloy steels with a high carbon content. It is characterized by more local carbide accumulation, mainly due to the fact that the ledeburite eutectic carbides and secondary network carbides in the steel are not broken and unevenly distributed during the forging process. Carbide segregation will reduce the forging deformation ability of steel, easily lead to cracking during fire forging, overheating and quenching of forgings during heat treatment, and cracking of cutting tool edges.

3. Bright lines

Bright lines are fine lines with reflectivity and crystal brightness that appear at the longitudinal fracture during forging. Most of them are distributed throughout the fracture, and most of them appear on the axis. Bright lines are mainly caused by alloy segregation. Slight bright lines have little effect on the mechanical properties of the material, and severe bright lines will reduce the plasticity and toughness of the material.

The above is an introduction to some problems encountered in forging processing. If you have other questions, please consult us.