- tyler@kirail.com

- +86 15603721115

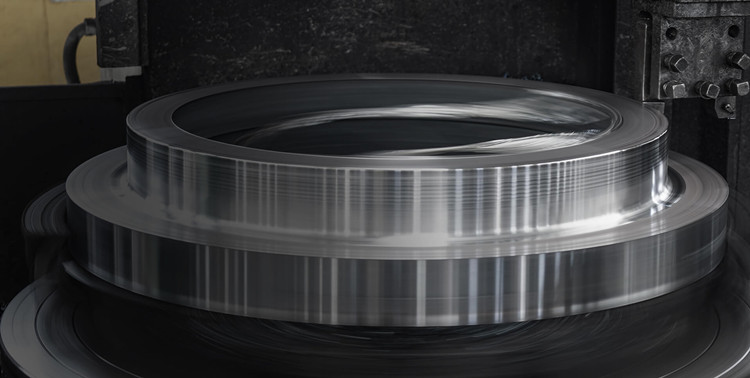

In the use of forgings today, if the temperature is not well controlled or the operation is careless, a series of defects will be caused in the production process, thereby reducing the quality of the forgings. In order to eliminate such defects in forgings, a series of improvements need to be made.

1. Improvement of metal parts

Improvement of metal parts is to avoid stress in sensitive parts of steel during work during the forging process. This can increase the relative density of metal materials, not only making their surface less smooth and dense, but also making them high aluminum alloys, which are easy to break when alloy steel is carburized.

2. Improve the appearance and specifications of steel castings

Improve the appearance and specifications of steel castings to make them closer to parts. This not only reduces the cost of metal composite materials, but also shortens the time of laser cutting, which can further improve the production efficiency of forged parts, which is far more efficient than the efficiency of drilling production and processing. The forging press has strong adaptability to forgings, and can not only carry out simple production and processing, but also produce parts with relatively complex shapes. Therefore, no or little drilling or solving is required in the entire manufacturing process. With the improvement of forging processing technology, the quality of forgings has been greatly improved, and the minimum forging defect rate has been greatly reduced. Therefore, as various industrial equipment, forgings can play a stronger role.

3. Improve forging materials

For special tools like Barr, the surface of the forging material will be affected during the forging process. Extended heat treatment methods are applied to forging materials to eliminate the different time characteristics of internal and external organizational changes of forging materials, reduce welding stress and structural stress, and ensure more reasonable cast steel material properties and service life. Forging materials have strong adaptability to forging machinery.