Forging Capabilities

Forgings | Raw Material | Size Min(mm) | Size Max(mm) | Weight Min. | Weight Max. | Heat Tr |

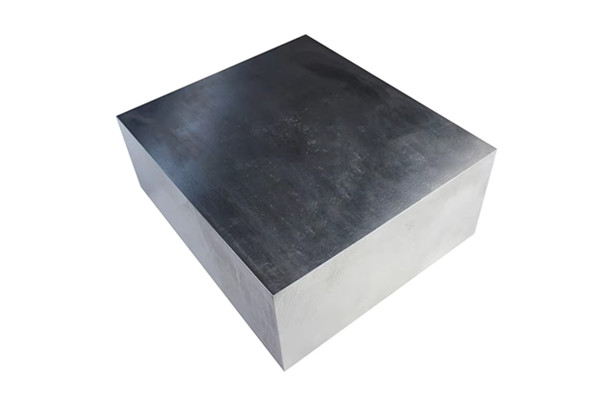

Block | Carbon Steel

Tainless Steel

Alloy Steel | 100X100X100 | 1500×1500×1500 | 7.85kg | 26000kg | Normalizing

Quenching

Tempering

Solution annealed |

Applications

Power plants, automotive industry, medical devices, aviation forging, petrochemical, component processing, offshore platforms, etc.

Production process

Forging process quality control: Raw material steel ingot storage (chemical composition detection) → unloading → heating (furnace temperature detection) → post-forging heat treatment (furnace temperature detection) → furnace discharge (blank inspection) → machining → detection (UT, MT, appearance size, hardness) → QT → detection (UT, mechanical properties, hardness, grain size) → finishing → detection (size) → packaging and marking (steel stamp, logo) → storage and shipment

Quality Assurance

Kingrail Parts is proud to be ISO 9001:2015 and AS 9100 certified. Our focus on quality and customer first enables us to produce forgings that meet your needs and exceed your expectations.

Get More Help

Please contact us for more information and a quote.