- tyler@kirail.com

- +86 15603721115

In forging heat treatment, due to the large power of the heating furnace and the long insulation time, the whole process consumes a lot of energy. For a long time, how to save energy in forging heat treatment has been a difficult problem.

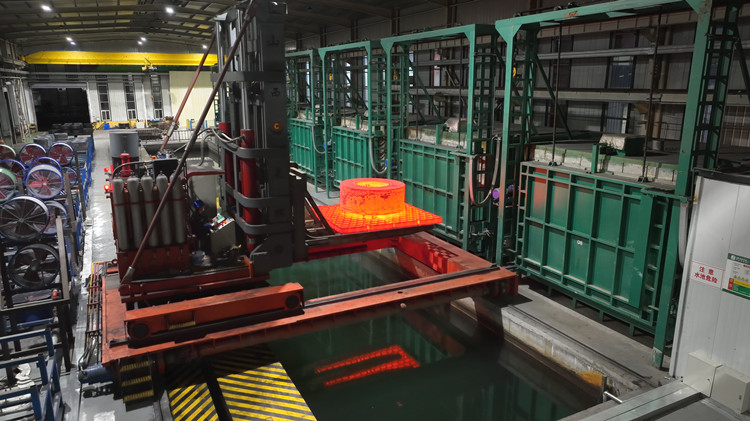

The so-called "zero insulation" quenching refers to the process of quenching and cooling immediately without insulation after the surface and core of the forging reach the quenching heating temperature after heating. According to the traditional austenite theory, the forging must have a long insulation time during the heating process to complete the nucleation and growth of austenite grains, the dissolution of residual cementite and the homogenization of austenite. The current forging quenching and heating technology is produced under the guidance of this theory. Compared with the current quenching process, "zero insulation" quenching saves the insulation time required for the homogenization of austenite structure, which can not only save 20%-30% of energy and improve production efficiency by 20%-30%, but also reduce or eliminate defects such as oxidation, decarburization, and deformation, which is conducive to improving product quality.

When carbon steel and low alloy steel are heated to Ac1 or Ac2, the homogenization process of austenite and the dissolution of carbides in pearlite are both fast. When the steel size is in the thin range, the calculation of heating time can ignore the insulation, that is, zero insulation quenching is achieved. For example, when the diameter or thickness of 45 steel workpiece is not more than 100mm, when heated in an air furnace, the temperature of the surface and the core is reached almost at the same time, so its uniform heating time can be ignored. Compared with the traditional production process with a larger heating coefficient (r=aD), the quenching heating time can be reduced by nearly 20%-25%.

Theoretical analysis and experimental results show that it is feasible to use the "zero insulation" process for quenching and normalizing heating of structural steel. In particular, for 45, 45Mn2 carbon structural steel or single alloy structural steel, the "zero insulation" process can ensure the requirements of mechanical properties; for 45, 35CrMo, GCrl5 and other structural steel workpieces, the "zero insulation" heating can save about 50% of heating time compared with traditional heating, with a total energy saving of 10%-15%, and an efficiency improvement of 20%-30%. At the same time, the "zero insulation" quenching process helps to refine the grains and improve the strength.