- tyler@kirail.com

- +86 15603721115

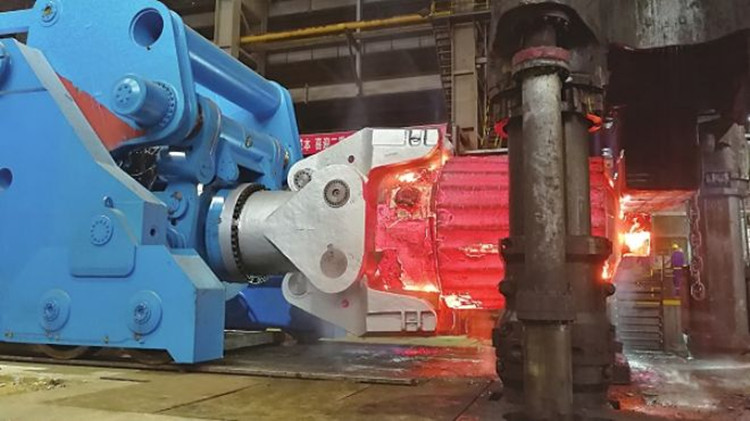

The drawing process is an important part of the production of large shaft forgings and has a huge impact on the quality of the final product. The drawing process ensures uniform density of the forging by reducing the cross-sectional area of the billet, increasing the billet length, and refining the ingot structure. This article will explore the various advanced drawing technologies currently available, including WHF, KD, FM, JTS, FML, TER, SUF, and the new FM forging method, and outline the unique principles and applications of these technologies in detail.

1. WHF (Warm Forging)

Warm forging (WHF) is a drawing process that combines the advantages of warm forging to reduce the negative effects of oxidation and decarburization. By controlling the forging temperature and deformation rate, WHF can obtain a finer grain structure, thereby improving the overall mechanical properties of the forged material.

2. KD (Kocks-Draw)

The Kocks-Draw (KD) process is an advanced drawing technology that uses grooved rollers to form and finish the billet. The process significantly enhances the structural integrity of the material by redistributing internal stresses and reducing surface defects. As a result, KD forged products have excellent strength, ductility, and fatigue resistance.

3. FM (Flow Manipulation)

Flow Manipulation (FM) is an innovative forging technology that uses custom die designs to direct the material flow during the drawing process. This method provides better control over grain flow and microstructure development, resulting in improved mechanical properties and more uniform material distribution.

4. JTS (Joint Taper Shear)

Joint Taper Shear (JTS) is a drawing technology that combines two or more tapered rollers to produce a shearing action to precisely control material flow. This method promotes homogenization of the grain structure and reduces the possibility of defects, making it an efficient and accurate processing method for large shaft forgings.

5. FML (Forging Mandrel Length)

Forging Mandrel Length (FML) is a method that uses a mandrel to support and shape the blank during the drawing process. This technology can simplify the process, improve dimensional accuracy, reduce material waste, and increase production efficiency.

6. TER (Tapered End Rolling)

Tapered End Rolling (TER) is an advanced drawing technology focused on improving the surface quality of forged products. TER minimizes surface defects and promotes a more uniform grain structure by shaping the billet using tapered rollers, thereby improving strength and fatigue resistance.

7. SUF (Surface Upset Forging)

Surface Upset Forging (SUF) is a deep drawing process that focuses deformation on the surface of a metal material, aiming to optimize the material's surface characteristics and improve overall performance. The technology is particularly effective in improving critical wear resistance and fatigue strength.

8. New FM Forging Methods

New FM forging methods continue to emerge, pushing the boundaries of traditional drawing techniques. By integrating innovative technologies such as advanced materials and computer-aided design, these cutting-edge methods provide new possibilities for improving the production performance and efficiency of large shaft forgings.