- tyler@kirail.com

- +86 15603721115

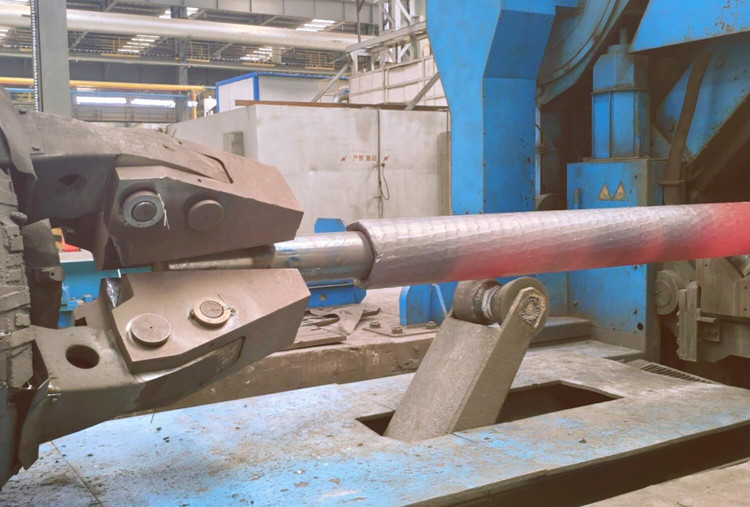

All forgings will undergo quality inspection before leaving the factory to ensure the quality of forged products. The following is the quality inspection process for forgings.

The inspection procedures for forging products are as follows:

1. All forgings should be cleaned before acceptance. Free forgings may not be cleaned.

2. Before the acceptance of finished products, the forgings submitted for inspection and acceptance should be checked against the accompanying cards one by one to see whether the batch number, alloy, state, specification, heat treatment furnace number, input amount, etc. are consistent with the accompanying cards, and then checked item by item according to the technical standards specified in the contract.

3. Final inspection requirements and acceptance rules Forgings should be in accordance with forging drawings, process regulations, technical conditions and accompanying process cards. The sampling location, direction and quantity of physical and chemical inspection samples should meet the requirements of technical standards and sampling drawings. The entire inspection process should be recorded in detail.

4. Review whether the physical and chemical inspection reports such as organization and performance are complete and clear, review them item by item, and deal with unqualified items.

5. After the final inspection, if the forgings are qualified, the inspector shall fill in the forging inspection certificate in accordance with the requirements of the contract, agreement or relevant documents.

6. After the inspection, unqualified forgings shall be clearly marked and isolated.

7. Make inspection marks and other marks (or hang signs) on the specified parts of the forgings